Expertise

J-TECH@POLITO provides expertize in:

- Custom joints for composites, polymers, metals, ceramics, and glasses; similar and dissimilar joints, multi-materials joints

- Joining (brazing, adhesive joining and soldering) for a wide range of applications, to name a few: automotive, aerospace, biomedical, energy production and storage, high temperatures, photonics, thermonuclear fusion (ITER); new generation fission reactors (Gen. IV); sealants for solid oxide fuel cells, ….

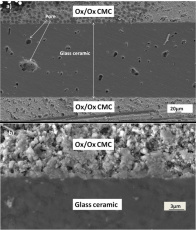

Joninig of Ox-Ox composites

Joninig of Ox-Ox composites

- Mechanical design and stress analysis, fatigue and impact tests of joined components

- Manufacturing technology and assembly processes for joined components

- CT-scan, High Temperature mechanical testing and Non-Destructive Tests on joined and non-joined components

- Advanced welding processes by means of friction stir welding (FSW), laser, and other welding equipment

- Advanced modelling and analysis of joints including experimental model validation and design capability for emerging processes

- Debonding of adhesive joints: modified adhesives including graphene nanoparticles and iron oxide particles exposed to microwave or induction heating

But also:

- Coatings by slurry technology, electrophoretic deposition or sputtering for every kind of substrates such as: polymers, textiles, metals, ceramics, composites, glasses, and more.

- Custom coatings for a wide range of applications, such as: energy production and storage, automotive, aerospace, biomedical, high temperatures, photonics and sensors, and more.